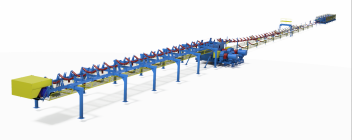

Stationary belt conveyor

Stationary belt conveyors of conventional design with the belt width from 400 to 2000 mm are intended for horizontal and inclined (up to 35°) transportation of bulk and lump materials with a bulk density up to 3.5 t/m3, as well as of units loads under the following conditions:

- atmosphere, type 1 as per GOST 15150 with the dust content of air not more than 200 mg/m3;

- relative humidity at 25°C not more than 98%;

- altitude above the sea level is 1000 m;

- supply line voltage fluctuation from -10% to +10% of nominal value.

The load transportation distance may achieve several hundred meters.

The belt is driven by a drive pulley and intermediate elements — troughed idlers — do not allow it to sag under the weight of a load and enhance the structure’s total stiffness preventing the conveyed loads against spillage. In the loading zone the conveyor can be additionally completed with impact rollers or with a cradle with shock-absorbing pads that helps to absorb the impact energy of the load lumps and prevent the belt against breaks.

Depending on a slope angle and a conveyed material the conveyors are completed with flat or chevron belts. The conveyors shall be manufactured in the climatic version U — for areas with the moderate climate, in the climatic version UKhL — for areas with the cold climate as per GOST 15150 and in the climatic version T — for areas with the tropical climate as per GOST 15151 of environmental classes 1, 2, 3, 4.

Scope of Application

The conveyor design may have different scheme that allows to adapt them to production conditions and geographical features of the area. It is allowed to use idlers with rollers with offset bearings.

The Company has a great experience in manufacturing of such type of conveyors. Over the last three years our Company designed and produced more than 200 units of stationary belt conveyors of different modifications: from KLS-500 to KLS-2000. Customers: NLMK, SGOK, PAO Severstal, Polyus Aldan AO, JSC “Belaruskali”.

Advantages:

- Higher operating temperature range: from -60°С to +50°С

- Easy operation and high reliability

- Possibility of the control system automation that ensures operation of the structure in hard-to-reach places and under severe climatic conditions, for example at very low temperatures

- Use of high-quality components made by manufacturers leaders in their industries that ensure the reliability of operation of the whole conveyor system

- Possibility of production of conveyors with different lengths up to the overland/long-distance conveyors (several km)

- Options, for example installation of heated pulleys to avoid freezing and snow build-up and to ensure the continuous operation of the equipment and avoidance of outage time.

Belt conveyor: what do the customers need

Survey of enterprises using the conveyor equipment showed that now customers pay great attention to the performance improvement. And they look for corresponding solutions from manufacturers to improve the belt conveyor efficiency.

The capacity is closely related to the operation reliability factor. The belt conveyor intended for loads shall be operated continuously — in this case it will be an excellent alternative to other mode of transport. Therefore, the manufacturers address simultaneously multiple tasks — performance improvement (belt speed) and prevention of time outages. For this purpose JSC “SIA “Akonit” offers equipment automation solutions and different monitoring systems for different types of belt conveyors. Now the belt speed sensors and the sensors gathering information on the condition of components in bottlenecks: loading, unloading, transfer points, etc, almost become an integral part of any project. Often and often the deep automation is required and the Company is ready to offer solutions in this field.

For further details as well as for information on implemented projects call by phone +7 (8172) 20-90-16. Our specialists will be happy to answer all your questions.

Отрасли применения продукции