Pulleys

Conveyor pulley: for which is it required?

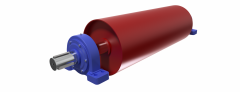

The conveyor pulley is one of driving elements of the conveyor system. In appearance it is a cylindrical tube with end faces and a solid shaft with seats for bearing units. The working surface of the conveyor pulley will be always larger than the belt width to avoid the potential slipping. This structure is made of high-quality steel to ensure the long-term operation.

The manufacturers produce some types of components. The drive pulley ensures the conveyor belt movement and is installed at the extreme points of the mechanism. The take-up (non-drive) pulley ensures the belt tension along its entire length and reduces a risk of slipping when transporting loads.

Advantages of conveyor pulleys made by JSC “SIA “Akonit”

The components are manufactured at the production site in Vologda. It is possible to manufacture pulleys for different belt widths up to the largest pulleys for overland (long-distance) conveyors. In addition we can carry out orders with specific and high requirements to quality of the conveyor system assembly units. The modern machine tools with lathe functions allows processing parts in 5 planes simultaneously ensuring the maximum accuracy and quality.

Conveyor pulley of nonstandard size

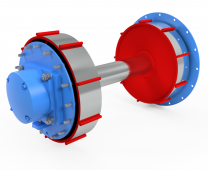

In February the conveyor pulley manufactured upon the individual request of customer was shipped from the JSC “SIA “Akonit” site in Vologda. It had a nonstandard size — more than 4 meters

The possibility to manufacture such conveyor pulleys appeared after commissioning of the complex of modern automatic machining centers with lathe functions. And it is not a single advantage that the customer of JSC “SIA “Akonit” takes. The components manufactured using these multipurpose machining centers are components of high quality and accuracy that enhances their performances and quality of assembly units of the conveyor system. We are also ready to manufacture pulleys for different widths of conveyor belts — from 500 to 2000 mm.

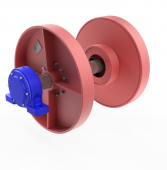

It is worth reminding that the standard range of conveyor pulleys made by JSC “SIA “Akonit” includes 4 types: drive and non-drive pulleys, pulleys with disks and beater bar pulleys— with the diameter from 250 to 3000 mm.

For further details on the possibility of customized manufacturing of pulleys call by phone +7 (8172) 20-90-16 or send a request to email: mail@npoakonit.ru.

Manufacturing of pulleys for conveyors

What can guarantee the quality of conveyor pulleys? From our point of view the following is required:

- own production site

- resources

- wish to be a leader in the industry

How does it help in manufacturing of pulleys for conveyors? JSC “SIA “Akonit” has its own production site in Vologda which is specialized in production of components for belt conveyors over the years. The in-house production is a possibility to control and improve every stage and therefore monitor and improve the quality of products. The resource base is a machine pool which was partially modernized in 2020. The site is equipped with automated multipurpose machining centers made by world leaders in machine tool industry. The possibility to machine parts of conveyor pulleys in several planes simultaneously not only reduces the production process and order production time but also improves the machining accuracy.

Wish to be a leader in the industry means the search for new technical solutions and their adaptation to customer’s needs. Therefore we can offer not only a standard set of equipment: drive and non-drive pulleys, pulleys with disks and beater bar pulleys — of standard sizes, but also carry out orders with customized sizes and requirements of our customers. And maintaining the quality and meeting the lead time.

For further details on the possibility of manufacturing of belt conveyor pulleys call by phone +7 (8172) 20-90-68 or send a request to email: mail@npoakonit.ru.

Belt conveyor pulley: how is the reliability ensured?

The pulley is a main element in the belt conveyor. The operation of the whole system depends on its quality. In order to improve the product quality in 2020 JSC “SIA “Akonit” implemented the RAZUM project by purchasing modern European equipment. From the date of operation of machines 100% quality of production is achieved. In prior years up to 10-15% of parts were required to be reworked. Therefore, the reliability of belt conveyor pulleys is improved and it saves time and money of our customers.

The quality is also achieved due to the process repeatability. The new equipment has the programmed path algorithm and only parameters of rough part are changed. It is not necessary to describe the tool path again and again and it minimizes the risk of errors. Moreover, the lead time of the part production is reduced as all operations are performed on the same machine tool and the time for changeover is not required.

An additional advantage — the possibility to produce the belt conveyor pulleys according to the customer’s drawings.

To learn more call by phone +7 (8172) 20-90-16 or send a request to email: sales@npoakont.ru. Our specialists will be happy to answer all your questions.