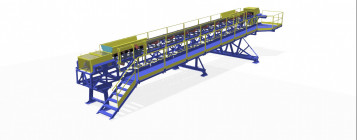

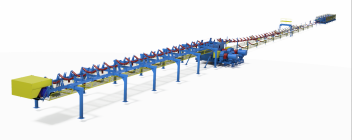

Pipe conveyor

Pipe belt conveyor is a specially designed belt forming a sealed, dust-proof pipe by means of radially located idlers. Special guiding parts (levers) open the belt at the loading and unloading areas.

Scope of application

Pipe belt conveyor is ideal for use where space is limited and for transportation of bulk materials without contamination. It is an environmentally friendly system for transportation of bulk materials which can be used at different areas with a possibility to make horizontal and vertical bends and angle of inclination up to 30°. They are capable to transfer the most of bulk materials with an acceptable speed.

The belt conveyor of such type is usually used in ports where the main problems are contamination and spillage.

Advantages:

- Environmental protection against dirt and dust

- Load preservation and spillage avoidance

- The possibility to operate on complex curved paths taking into account horizontal and vertical bends that allows transporting loads at large distances without additional transfer stations.

- The unit cost of the load transported with pipe belt conveyors is less than using other means of transport.

Operation

Operation of pipe conveyors, based on the increase in pressure between the loads and the belt, is that the bulk load continuously supplied to a flat part of the belt is carried away by the belt and is compressed when the belt is shaped into a pipe. There are different types of belt edges connection: V-type, zip, magnet, rollers and squeezing shells.