Rollers

Production of conveyor rollers - how is the quality ensured?

The service life of conveyor rollers, including belt rollers, is one of the key parameters for customers. Service life time = quality and reliability of products. How to achieve high performance?

At the conveyor rollers production plant in the Republic of Tatarstan, which was put into operation at the end of October, quality monitoring is carried out at each stage of production. It starts with the storage of raw materials: pipes are stored in a dry and warm place to avoid rust, and rubber gaskets ensure that the shape and ovality remain intact.

Perfect precision of belt conveyor rollers

On the cutting line, the pipe takes the shape of a perfect circle, it is cut, bored and chamfered. The technology for simultaneous processing of two parts with the cutting head is patented. All workpieces go through a cleaning station. The machine for assembling and welding of the shells ensures that the weld strength is higher than that of the metal of the workpieces themselves. Operations on the belt conveyor roller assembly line are performed with the roller axis strictly centered, ensuring perfect accuracy of component installation.

At this stage, each roller is monitored for three parameters: axial displacement, radial run-out and rotational resistance torque.

The last stage of control: on the line of coating and assembly of conveyor rollers.

Where to buy conveyor rollers?

When choosing conveyor rollers, customers pay attention to two key parameters: the service life of the components and terms and conditions of the cooperation with the supplier of spare parts.

The operating life depends on the materials and the technical solutions used by the conveyor roller manufacturer. Akonit components are produced at the production site in the Republic of Tatarstan (the city of Elabuga). Production site is equipped with modern equipment: pipe cutting line, welding machine, assembly line, painting and packaging of conveyor spare parts. Unique developments of the SIA "Akonit" designers, which are aimed at improving the quality and reliability of the roller and its service life, are used in the production. Now it is 30,000 hours, and in the future it will increase by 50%. Components can operate in harsh climate and aggressive environments, for example, in a chemical plant or in mines.

Terms of work with customers are based on the principle of maximum flexibility. The plant's capacity allows to produce up to 1 million rollers of various sizes per year . Under certain conditions, it is possible to execute the order within 3 days. This eliminates long downtime due to failure of key components. You can order and purchase conveyor rollers with different types of bearings, axle variants and other parameters. The manufacturer of conveyor rollers is also ready to produce components according to individual sizes and requirements and without limits on the minimum batch.

To learn more about production of conveyor components and to order products, please call +7 (8172) 20-96-16 or fill out the data sheet.

Conveyor rollers - according to the customer's drawing

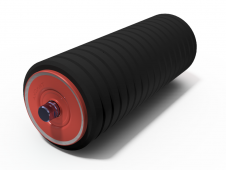

SIA "Akonit" offers a wide range of conveyor rollers - flat, impact, training, etc. More information about the range can be found on the website in the "Products" section. These are standardized components that meet the basic requirements of most customers.

However, if necessary, we can produce conveyor rollers in accordance with individual customer requirements - according to the provided drawings. Such a need arises when the customer needs, for example, spare parts of reinforced design or of a non-standard size. Timing and cost of components will be calculated individually.

In addition, if necessary, specialists of SIA "Akonit" will perform drawings of conveyor rollers, taking into account all the wishes of the customer, which can later be used to manufacture components.

If you need conveyor rollers, there are no necessary schemes, but there are specific requirements dictated by your production, please contact SIA Akonit. The order will be executed well and in optimal time.

Dimensions of conveyor rollers: a wide choice for any duty

SIA "Akonit" offers the customers different types and sizes of rollers for conveyor equipment. Capacities and technical equipment of production sites in Tatarstan and Kirov allow to produce flat and impact rollers of 10 different diameters - from 63.5 mm to 194 mm. They can be used for belts of different widths: from 400 mm to 2400 mm. The length of the conveyor rollers varies from 165 mm to 2200 mm. The type of bearing varies depending on the diameter. For rollers ø from 63.5 mm to 108 mm, bearing 204 is used, and for ø 114, 127 mm, 205, 207, 306, 307 bearings are used.

The shell thickness is from 3 mm to 6.5 mm. If necessary (if the load on the conveyor roller is expected to be high), the shell thickness can be increased. All batches of manufactured products are subject to mandatory quality control. This allows them to operate in an aggressive and rough environment, with temperature fluctuations from +30 C to -50 C degrees.

The company is also ready to make conveyor rollers according to the size and drawings of the customer. Production time is determined individually, the cost depends on the size of the batch.

For more information, call+7 (8172) 20-90-16 or e-mailsales@npoakonit.ru.

Conveyor rollers - what is the price?

The cost of conveyor rollers depends on several parameters: type, diameter, batch size. The company's specialists are constantly studying the state of the market and demand. The obtained data show that the price of Akonit conveyor rollers is competitive and meets the expectations of the customer.

The price of a flat conveyor roller starts from 500 rubles. The cost can vary up to several thousand rubles. The larger the diameter and the number of design features, the higher the price will be. For example, a flat roller of large diameters can cost 3-3.5 thousand rubles. Impact roller, which softens the impact of the load on the belt and prevents its wear, in a simple design (minimum diameters) costs from 1.5 thousand rubles. Design features and an increase in diameter can raise the price to 4.5 thousand rubles.

What is important when you need to purchase a conveyor roller?

Remember that the final cost of a batch of conveyor rollers often includes shipping! Therefore, when ordering, pay attention to this parameter and ask the manager - what the price is quoted: with or without shipping. You can also ask to calculate the order without delivery and to arrange pickup.

Another important factor is the urgency of the order. In this case, not only the cost of the product itself, but also its transportation to destination: Rates for urgent delivery should be clarified either with the manager or with the shipping company.

For more questions about the price of conveyor rollers, please call +7(8172)20-90-16 or e-mail mail@npoakonit.ru