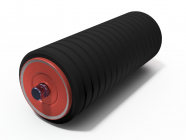

Flat rollers (RG)

The roller is the most important element for various types of conveyors. It is designed to support and ensure the movement of the conveyor belt. The main components of the roller are: a fixed axle, a shell (pipe), two bearing housings with ball bearings, labyrinth seals with grease and metal caps, locking rings. The connection concept of the bearing housing with the shell can be either welded or rolled.

Industries of application:

Mining industry, coal industry, metallurgy, chemical industry and other industries that use conveyor transport in their work.

Advantages:

- Improved product characteristics (radial run-out, axial play and torque resistance);

- increased reliability of the bearing unit (labyrinth seal);

- The conveyor roller is designed for rough working conditions (high dusting, high humidity, impact loads, high speed).

We strive to produce high-quality conveyor roller and therefore impose strict control requirements on our products:

- tougher requirements for the materials used (input control);

- compliance of the conveyor roller with GOST;

- 100% bearing check;

- inter-operational control at all stages of the roller manufacturing process;

All this ensures a long service life of the rollers without breakage or replacement.

Shell made of steel pipe from 3.5 - 6 mm

JSC SIA Akonit offers 9 variants of flat roller. The price of conveyor rollers is determined individually, depending on the production time and the batch required. The price of the roller may include its shipping at the request of the customer.