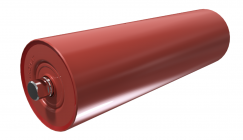

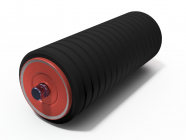

Flat training idler (threaded)

Flat training idler prevents belt from misaligning under loads and serve for belt tracking. There are carrying and return training idlers that are installed at 10-15 m spacing in the intermediate part of equipment as well as in areas where there is a risk of belt edge damage in case of misaligning. Preventing belt from misalignment, a training idler is an important component in the bulk handling system

Specifications:

Shell thickness – 3.5 – 6 mm

JSC SIA Akonit offers the following training idler diameters: 89, 102, 108, 127, 159 mm with any bearing type in accordance with the Customer’s technical specification.

Price is defined individually depending on quantity and production period. Delivery can be included as per Customer’s requirement

Applications:

Mining, coal, metallurgy, chemical and other industries where conveyor equipment is used.

Advantages:

- Improved product characteristics;

- Bearing housing increased reliability (labyrinth seal);

- Roller is designed for operation in severe operation condition (high level of dusting and moisture content, impact loads, high speed).

We are striving for manufacturing a conveyor roller to the highest quality standard and therefore we apply stringent quality requirements:

- stringent requirements to the material used (incoming control);

- 100% bearing check;

- in-process control at all stages of the technological process of roller production;

All this ensures a long-term roller operation period without failures and replacement.

Diameter:

89, 102, 108, 127, 133, 159 mm

Length:

150 – 400 mm

Bearing:

204, 205, 207, 305, 306, 307