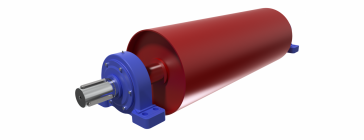

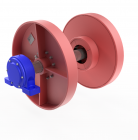

Non-drive pulleys

Belt conveyor component

Pulleys are one of the types of belt conveyor equipment. They are in charge of the belt tension, of the belt direction change, are good for connection with the belt and finally ensure continuous operation of the whole system.

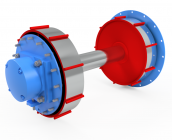

The belt conveyor pulley consists of a cylindrical shell, a shaft, a cast steel disk and a clamping set. If necessary, it can be completed with other elements. It is possible to manufacture pulleys with removable plates allowing to replace the lagging without dismantling the pulley from the conveyor.

The production of pulleys with a bearing of series 35 was mastered. The shaft can be connected to the hub through the key or by means of a clamping set that allows making the structure dismountable and repairable.

Advantages:

- Manufacturing for any belt widths of different diameters

- Optimal terms and costs of manufacturing

- Possibility to manufacture in accordance with the customer’s drawings

- The strength analysis in Nastran — leading world finite-element system that allows obtaining optimal analysis data and results

- The equipment is produced at the production site where the extensive retrofitting and upgrading have been performed. It allowed improving the product accuracy and quality. Learn more about the project in the RAZUM News section.

What do you have to consider when purchasing?

When selecting a contractor you should take into account the following parameters: experience, production range, manufacturing and delivery periods, possibility to meet individual requirements. JSC “SIA “Akonit” focuses on work with specific customer’s requirements. In addition, the production site has arranged and implemented a multi-stage system for monitoring component manufacturing process. Therefore, the manufacturer ensures a consistent quality of production, its reliability and high performances.

Take-up pulley of the belt conveyor

The purpose of a take-up pulley or, in other words, of a non-drive pulley is easy to guess by its name. It is required for constant belt tension in the belt conveyor: to exclude its sagging, to adjust the travel, to pull during motion and to avoid slipping. A take-up pulley shall be installed in the middle of the conveyor on the return side of the belt at the place of its bending or at the tail. Take-up pulleys are used in horizontal or inclined belt conveyors.

To ensure a better contact between the conveyor pulley and the belt a lagging is used. JSC “SIA “Akonit” offers pulleys lagging with rubber, low-combustible rubber, rubber-ceramic and metal-ceramic. The pulley sizes are determined based on the conveyor system length and the belt width. We can also manufacture conveyor pulleys of nonstandard size according to the individual requests and drawings of the customer.

Components for the belt conveyor are manufactured using the modern machine pool that ensures their high quality and the possibility to be operated in different climatic conditions and environements.

For further details on the manufacturing of take-up pulleys call by phone +7 (8172) 20-90-16 or send a request to email: mail@npoakonit.ru.

Akonit manufactures 4 types of components: drive pulleys, non-drive pulleys, pulleys with disks and beater bar pulleys. A drive pulley ensures the movement of the belt on the stationary belt conveyor. For a more reliable contact with the belt, it is lagged with a rubber. A non-drive pulley protects the belt from slippage, uncontrolled stops, and also serves to change the belt direction on horizontal conveyors.